College of Engineering & Management, Kolaghat

Approaved by AICTE New Delhi

Affiliated to MAKAUT West Bengal

NBA Accredited, Dept of CSE, ECE and EE

Life Institution Membership of IEI

Alumni Registration Form

Highlights

| H.O.D | Dr. Tarun Kanti Pal |

|---|---|

| hodme@cemk.ac.in | |

| Mobile | +91 6297669917 |

| Phone | - |

| Type | Name | Duration | Intake |

|---|---|---|---|

| UG | B. Tech. in Mechanical Engineering | 4 Years | 30 |

Departmental Links

1. Study of Boiler Cut Models

2. Study of IC Engine Models

3. Valve timing Diagram: Draw the Valve timing Diagram of a Single cylinder 4S Diesel and Petrol Engines.

4. Load Test of a 4S Diesel Engine: To Study the Change in Fuel Consumption and Efficiency with Change in Loading with the help of Electrical Load Box, Draw also the Graphs of FC vs. BHP, BSFC vs. BHP, Efficiency vs. BHP.

5. Load Test on Single Cylinder 4 Stroke Petrol Engine by Rope Brake Dynamometer to Perform Load Test on a Petrol Engine and to Calculate ( i ) BHP , ( ii ) FHP ( iii ) IHP ( iv ) BSFC ( v ) Indicated Thermal Efficiency ( vi ) Brake Thermal efficiency ( vii ) Mechanical Efficiency ( viii ) Volumetric Efficiency

6. Load Test on Single Cylinder 4 Stroke Diesel Engine by Rope Brake Dynamometer to Perform Load Test on a Diesel Engine and to Calculate ( i ) BHP , ( ii ) FHP ( iii ) IHP ( iv ) BSFC ( v ) Indicated Thermal Efficiency ( vi ) Brake Thermal efficiency ( vii ) Mechanical Efficiency ( viii ) Volumetric Efficiency .

7. Heat Balance of 4 Stroke Diesel Engine by Rope Brake Dynamometer to Study the percentage losses that occur in Diesel Engine.

8. Performance Characteristics of Diesel Engine at Different rpm by Rope Brake Dynamometer : To Perform Load Test On a Diesel Engine and Calculate (i) Brake power, (ii) Fuel consumption, (iii) Air Consumption, (iv) Brake Thermal Efficiency (v) Volumetric Efficiency.

9. To find the Calorific Value of any fuel by Bomb Calorimeter.

10. To find out the Flash Point and Fire Point of Liquid fuel or Oil by means of Cleveland Apparatus.

11.To find out the Cloud and Pour Point of Liquid fuel

12. To study the Diesel Smoke meter.

13. To visit a Thermal Power Station.

1.4 – Stroke 2-Cylinder Diesel Engine 14 BH.P. Make: Alimgir Completed with 3-Phase, 8-KVA, Pawertone make Alternator, Fuel Tank, Water Tank & Pump, Control Panel, Tachometer, etc.

2. 4-Stroke 4-Cylinder Petrol Engine 13 BH.P. Make: Ambassador Completed With Alternator all Spark Ignition system, Self Starter & Control Panel etc.

3. 4 Stroke single cylinder Diesel Engine with rope brake dynamometer,5hp 1500 rpm

4. 4 Stroke single cylinder Petrol Engine with rope brake dynamometer,3 hp, 3600 rpm

5. 4 stroke diesel Engine for valve timing diagram.

6. 2 Stroke Petrol Engine for valve timing diagram

7. 4 Stroke Petrol Engine for valve timing diagram

8. 4 Stroke/ 4 Cylinder/water cooled 10 HP/1500 RPM/Vertical Petrol Engine Test rig/With Morse Test facility

9. Cut Models (Boiler): a)Cochran Boiler b)Vertical Water Tube Boiler c)Babcock & Wilcox Boiler d)Lancashire Boiler e) Locomotive Boiler

10. To find out the Flash Point and Fire Point of Liquid fuel or Oil by means of Cleveland Apparatus.

11.Cut Models (Automobile): a) Two stroke Petrol Engine b) Four stroke Petrol Engine c) Four stroke diesel Engine d) Gear Box e) Gear Box with Clutch f) Differential Gear Assembly g) Demo of Differential Gear

12. Smoke meter.

13. Bomb Calorimeter

14. Pour & Cloud Point Appts.

15. Flash & Fire Point Appts.

Total Cost: 10,79,481

Area = 123.24 Sq. Mts.

Sheet No 1:Line, Lettering And Dimensioning

Sheet No 2: Curves

Sheet No 3: Scales

Sheet No 4:Projection Of Points And Lines

Sheet No 5: Projection Of Planes

Sheet No 6: Projection Of Solids

Sheet No 1: Isometric Projection

Sheet No 2: Section Of Solids

Sheet No 3: Development Of Surfaces

Sheet No 4: Interpenetration Of Surfaces

Sheet No 5: Machine Drawing

Sheet No 6: Riveted Joints, Nut And Bolt

Sheet No 7: Auto-Cad

Area = 90.06 Sq. Mts.

Analog UTM of capacity 20 Ton

2.Mechanical Extensometer

3.Torsion Testing Machine of capacity 60 Nm

4.Brinell & Rockwell Hardness Machine

5.Spring Testing Machine

6.Strain Gauge Trainer Kit

7.Coefficient of friction measurement set up

8.Set up for measurement of speed ratio

Total Cost: Rs. 7,20,925

Impact Testing Machine (Izod & Charpy)

Erichson cupping tester

Fatigue Testing Machine

Total Cost: Rs.1,83,300

| Name of The Laboratory | Area (Sq. m) | Major Equipments |

|---|---|---|

| Fluid Mechanics & Hydraulics Laboratory ME 491 | 99.34 |

i. CLOSED CIRCUIT APPARATUS FOR DETERMINATION OF MINOR LOSSES IN PIPE LINES DUE TO AN ELBOW, BEND, SUDDEN EXPANISION & CONTRACTION xii)Pitot tube apparatus

|

| Name of The Laboratory | Area (Sq. m) | Major Equipments |

|---|---|---|

| Auto-CAD Laboratory | 51.66 | 1. 30 Nos. of PC 2. Latest Auto-CAD Software 3. LCD Projector 4. Laser jet Printer |

Lathe (4.5’) with all accessories- 8 Nos.

Shaping Machine with all accessories- 4 Nos.

Universal Milling Machine (Horizontal)with accessories- 1 No.

Universal Milling Machine (Vertical) with accessories- 1No

Drilling Machine- 1No.

Bench Grinder- 1No.

CNC Lathe (MTAB)- 1No.

Different Machine Shop Equipments and Tools.

Color charts for different Machines

MANUFACTURING A JOB BY LATHE

MANUFACTURING A JOB BY SHAPER.

MANUFACTURING A JOB BY MILLING.

MANUFACTURING OF SPUR GEAR & "V"- BLOCK

EXPERIMENT ON CHIP THICKNESS RATIO OF TURNING PROCESS

EXPERIMENT ON L.T.D.

Belt & Disc Sander: Capacity 48”x6”- 1 No

Vertical Band Saw, W.D.12”, Size of Table 17.75”x17.75”- 1No.

Circular Saw ( Wood Cutting): SD-12” Table size 22”x 22”- 1 No.

Bench Surface Planner: Capacity-6”- 1 No.

Carpentry Vice- 14 Nos

Different types of Carpentry hand tools like Saws, Chisels, Mallets, Planners, Files & different Marking & Measuring tools etc

Wood Working Lathe- 1No.

MAKING THE CROSS- HALVING JOINT.

MAKING THE TEE - BRIDLE JOINT.

MAKING THE DOVE-TAIL JOINT.

Piller Drill Machine: Capacity-3/4”- 3 Nos.

Double Ended Bench Grinder GHD-6”- 3 Nos.

Semi Hydraulic Hacksaw: 1HP/AC/3Ph/1440rpm. – 1 No.

Fitting Vice- 14 Nos.

Different types of fitting tools like Hacksaw, Files, Chisels, Hammer, Punch, Taps, Dies & different types of Marking & Measuring tools etc.

Measuring Instruments: Vernier Caliper, Height Gauge, Micrometer Inside/ Outside, angle gauge Bevel Protector etc.

MAKING A PATTERN ON METAL PLATE

To Measure an External Diameter of a given sample by Outside Caliper, Vernier Caliper and Outside Micrometer

To Measure an Internal Diameter of a given sample by Inside Caliper, Vernier Caliper and Inside Micrometer.

To Measure the Height and Inclination with Horizontal of a given sample by Height Gauge and Angle Gauge Bevel Protector.

MMA Welding Transformer Set 1Ph,440V,AC, 200Amps.- 4 Nos.

Spot Welding Machine- 1 No

Gas Welding & Gas Cutting Set (Including Torches, Regulators, Nozzles and Hoses etc.)- 4. 2 Set.

Brazing Set with accessories- 1 Set.

CO2 MAG Welding Machine

Name of Experiments/ Jobs

BUTT JOINT BY MMA WELDING

JOIN TWO METAL PLATES BY SPOT WELDING

MAKING A LAP JOINT BY GAS WELDING

MAKING A "T" / FILLET JOINT BY CO2 MAG WELDING

Hand Shearing Machine, Size-12”- 1 No.

Eccentric Press- Pressure Capacity- 2 Ton. – 1No.

Circle Cutting M/c Size24”- 1 No.

Top & Bottom Seaming M/c- Max. Dia.8”, Max. Height 10”- 1 No.

Sheet Rolling M/c. - 1No

Edge Folding M/c. – 1No

Anvil With 5 Stake Set- 3 Sets

Soldering Equipments- 2 Sets

MAKING A RECTANGULAR TRAY BY TIN SMITHY & SOLDERING.

MAKING A FUNNEL BY TIN SMITHY & SOLDERING.

Muffle Furnace

Different types of Foundry tools.

Different types of wooden patterns.

Different Sand Testing Machines.

Making a wooden pattern .

Making of Sand Moulding and Casting.

Making of core.

Sand Testing.

Area: 78.96 Sq. Mts.

Major Equipments in the Shop:

1. Smithy Hearth Furnace- 2 Nos.

2. Anvil with Stand- 6 Nos.

3. Different forging tools

Activity of the Shop:

Workshop Practical - List of Experiments / Job

1. Job performed by Drawing down operation

2. Job performed by Upsetting operation

3. Job performed by Forge welding process

Area = 60 Sq. Mts.

1 HEAT TRANSFER IN FORCED CONVECTION : 1 No,

2 HEAT TRANSFER IN NATURAL CONVECTION: 1 No,

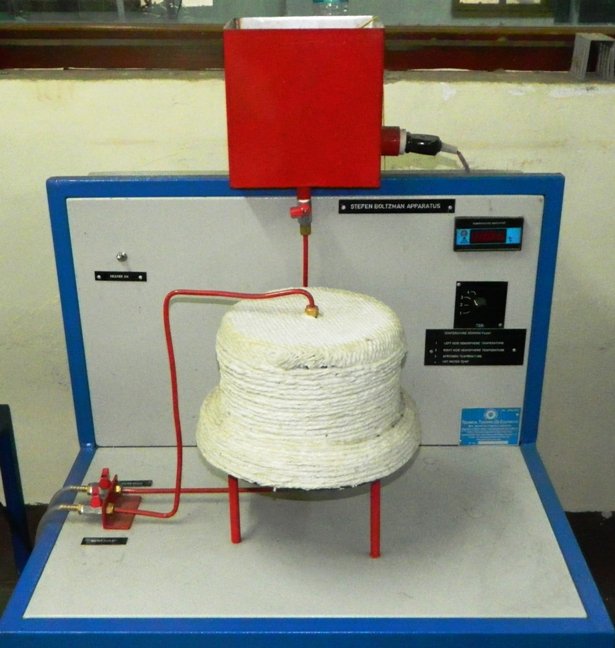

3 STEFAN BOLTZMAN APPARATUS : 1 No,

4 EMMISSIVITY MEASUREMENT APPTS. 1 No,

5 PERFORMANCE TEST ON AIR CONDITIONING TEST RIG : 1 No,

6 DETERMINATION OF C.O.P. OF VAPOUR COMPRESSION CYCLE ( REFRIGERATION TEST RIG ) 1 No,

7 PARALLEL FLOW / COUNTER FLOW HEAT EXCHANGER: 1 No,

8 THERMAL CONDUCTIVITY OF LIQUIDS : 1 No,

9 THERMAL CONDUCTIVITY OF METAL BAR 1 No,

10 COOLING TOWER TEST RIG : 1No,

Total cost:4,53,500

List of Equipment & Quantity of Metrology & Measurement Lab, ME594.

Area = 32.4 Sq. Mts.

1 Outside Micrometer 0-25 mm, (Mitutoyo) 2 Nos,

2 Outside Micrometer 25-50 mm, (Mitutoyo) 2 Nos,

3 Vernier Caliper 300 mm, (Mitutoyo) 2 Nos,

4 Slip Gauge Set, (Mitutoyo) 1 No,

5 Gear Tooth Micrometer, (Mitutoyo) 1 No,

6 Disk Micrometer 0-25 mm, (Mitutoyo) 1 No,

7 Bevel Protracter 150 X 300, (Mitutoyo) 1 NO,

8 Digimatic Outside Micrometer 0-25 mm, (Mitutoyo) 1 NO,

9 Dial Indicator LC .01 Range +/-0-100mm with Magnatic Stand, (Mitutoyo) 4 Nos,

10 Screw Thread Micrometer ,(Mitutoyo) 1No,

11 Profile Projector ,(Mitutoyo) 1No,

12 Surface Roughness Tester SJ210 –Standard Set with Connecting cable,(Mitutoyo) 1No,

13 Granite Surface plate 600X600X130,(Mitutoyo) 1No,

Total Cost: 5,39,700

Area: 60 Sq. Mts.

Equipments:

1 STATIC AND DYNAMIC BALANCING APPARATUS (Balancing Of Revolving Masses Apparatus) 1 No,

2 UNIVERSAL GOVERNOR APPARATUS 1 No,

3 MOTORISED GYROSCOPE 1 No,

4 CAM ANALYSIS APPARATUS 1 No,

5 BALANCING OF RECIPROCATING MASSES APPARATUS 1 No,

6 UNIVERSAL VIBRATION APPARATUS 1 No,

Total Cost: 7, 94 ,000

ANSYS software for 5 users

3D printer

Rapid prototyping machine

Vickers microhardness tester

Olympus microscope

5 axis robot, MTAB

P.O. Kolaghat Thermal Power Plant Township, Purba Medinipur,

Pin: 721171, West Bengal

+91 8617653058

Admission Helpline: 9609064108; 033 6902 9851

director@cemk.ac.in

Copyright © CEM, Kolaghat. All Rights Reserved.